Germany. With the advancement of trends such as electrification, software-defined vehicles, and automated driving, the automotive chassis is consolidated as a strategic axis in the architecture of modern vehicles.

In this context, ZF presents a substantial update of its Chassis 2.0 strategy, which combines intelligent components, by-wire technologies and digital platforms aimed at more connected and efficient mobility.

Chassis 2.0: Technology integration and advanced system-ready components

ZF is industrializing steer-by-wire and brake-by-wire technologies, eliminating mechanical links in favor of electronic solutions that enable new driving functions. The series production of the NIO ET9 with a fully electronic steering system from ZF marks a significant step forward in this field. In addition to this project, there are contracts with two other Chinese manufacturers and Mercedes-Benz, which will integrate this technology from 2026.

"At ZF, we benefit from this trend in two ways," explained Dr. Peter Holdmann, Member of the ZF Board of Management and responsible for Automotive Chassis Technology. "First, because of the expected global increase in demand for system-ready components, such as our steer-by-wire or brake-by-wire solutions. In addition, there is a strong demand for new and compelling features that seamlessly coordinate these components and deliver great benefits to end users."

In addition to the steering and braking systems, ZF maintains a prominent position in damping. With solutions such as the semi-active CDC (Continuous Damping Control) system and the sMOTION asset, the company has a 40% share of this segment globally. In the direction of the rear axle, its AKC system leads with 73% of the market, reaching up to 80% in Asia.

"The Chassis 2.0 approach responds exactly to the current market requirements," said Dr. Holdmann. "We anticipate that this segment of our portfolio alone will account for approximately 33% of the global market by the end of this decade, generating total revenues of around €4.8 billion. We are poised to establish market and technology leadership positions in all key segments of our Chassis 2.0 portfolio."

ZF is also advancing its hardware-agnostic software development strategy, positioning itself as a comprehensive supplier within the auto parts ecosystem. Its cubiX platform enables dynamic chassis management with components from different manufacturers, making system integration easier and shortening development times.

A notable new feature is cubiX Tuner, a tool that automates the customization of the control unit with the parameters of each manufacturer, streamlining calibration processes.

"This directly responds to a key demand from customers in all markets, especially in Asia: to speed up development processes and reduce costs," explained Philippe Gasnier, Development Director of the Chassis Solutions Division.

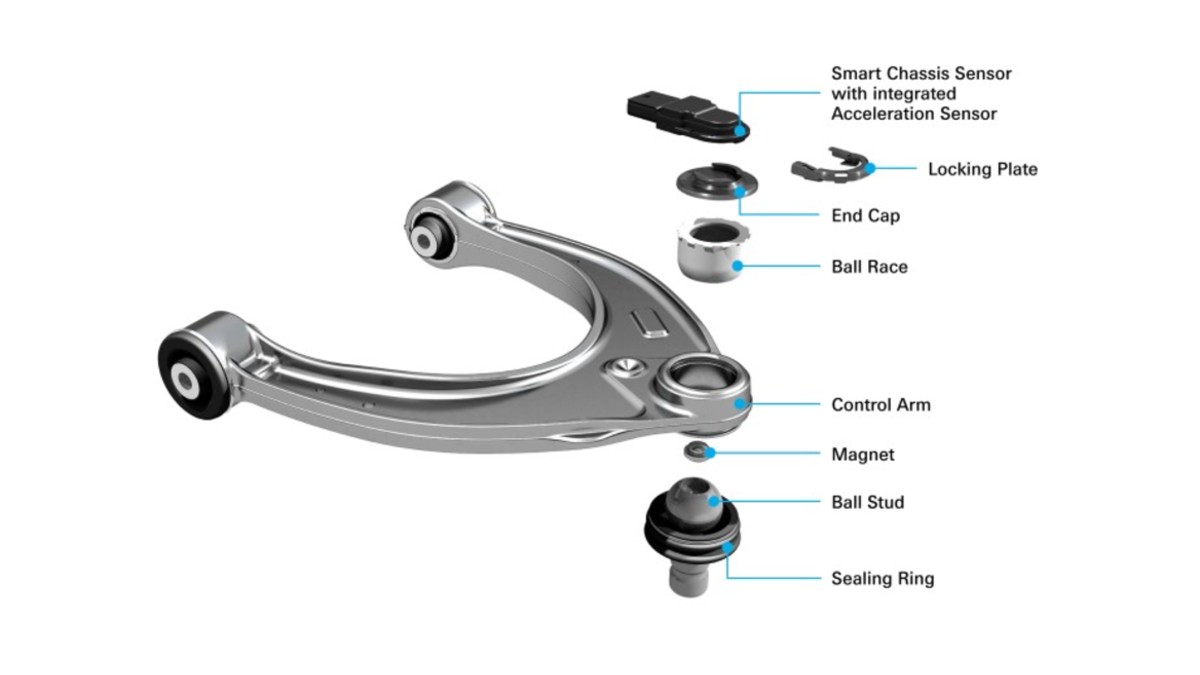

Sensors and Predictive Maintenance: The Future of Vehicle Monitoring

The development of the Smart Chassis Sensor, already in production on the Cadillac CELESTIQ, represents a step towards continuous monitoring of chassis condition. This sensor, integrated into a ball joint, measures accelerations in three dimensions and powers the Chassis Health system, designed as a tracker of the vehicle's mechanical condition.

Thanks to the use of artificial intelligence, this solution makes it possible to anticipate failures and facilitate predictive maintenance schemes, with relevant applications for manufacturers, auto parts distributors and workshops.