The opening of new markets in the Americas is part of the sustained growth of this expert company in the automotive sector, which gained further momentum 40 years ago with the acquisition of the Verfaille family.

By Aftermarket International

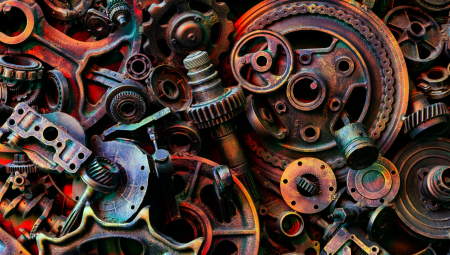

Ninety years ago in the borough of Hounslow, west of Greater London, Standard Link Innovation Limited could barely envision a growing world beyond the River Thames. However, barely a year after being established as SIDEM, the main centre of activity of this manufacturer specialising in the design and production of parts and suspension for the aftermarket had already moved to Antwerp, Belgium.

It was 1934. That year, a production unit for automotive spare parts was set up at a plant in Audergherm, on the outskirts of Brussels. Thus began the story of a company that over time would stand out for the quality and range of products, manufactured in Europe, becoming known beyond borders and other continents.

An Unstoppable Momentum

In 1983, Walter Verfaille acquired SIDEM and took over the company. His daughter, Gwen Verfaillie, who decided to follow in his professional footsteps after his death in 2010, now leads the company as CEO.

"When my father bought SIDEM in 1983, he was able to give the company a new direction. Production was moved from Lichtervelde to Roeselare (Belgium) before opening the production plant in central Europe. Their passion and entrepreneurial spirit have always inspired me," says Verfaillie, who started working at Sidem right after graduating, and because of his family history he was not new to the automotive world.

In 1986, just three years after the acquisition of his father, the company's growth would become evident when it moved to new facilities in the Belgian city of Roeselare with 10,000 square meters.

At the beginning of this century, in 2001, the company opened a plant in Romania and increased its production capacity significantly. A decade later, in 2011, and with Gwen Verfaillie in charge, SIDEM moved to an automated distribution center in Gullegem, Belgium. The new headquarters reached 12,000 m2 within a 27,000 m2 business park.

This expansion led to a further expansion of the SIDEM product range: suspension arms, ball joints, tie rods, axial joints, bushings, stabilizing linkages, strut mounts and steering rack bellows. Today, for almost all vehicles (personal and light commercial), including European, Asian and domestic, SIDEM has the solution with a product coverage of 95% that translates into 9,000 SKUs and more than 4 million parts available in inventory.

Since 2019, SIDEM has had a digital catalog where customers can search for steering and suspension parts.

From Europe to the world

As Iwan Loewen, Business Development Manager for North and South America at Sidem, explains, all of the company's products come from Romania. Each part developed with the longest service life, easy installation and maximum safety on the road in mind, is shipped to Belgium, and from there distributed worldwide.

"Our success on a global scale is undoubtedly due to our long-standing partnership with distributors in local markets around the world," says Gwen Verfaillie.

Gwen further highlights SIDEM as the "one-stop-shop" specialist with the best product coverage in the industry. "The most important reasons to work with Sidem are quality, reliability and stability. That's why customers rely on Sidem as their long-term, reliable partner," he emphasizes.

This is what has motivated partners outside Europe: from sales agents for the Middle East and Africa to making the leap to the Atlantic and growing throughout the Americas with clients in countries such as the United States, Canada, Mexico, Puerto Rico, Brazil, Paraguay, Chile and Uruguay. SIDEM also collaborates with commercial agents in countries such as Ecuador, Peru and Bolivia.

Certified quality

"If, from experience, SIDEM believes that the quality of the original equipment can be improved, the part is redesigned," says the company, which is audited by external organizations. The Quality Management System is accredited according to ISO9001, ISO14001 and ISO45001. SIDEM is also certified according to IATF16949.

In addition to focusing on the aftermarket, SIDEM is also an OEM supplier to several premium vehicle manufacturers.

"We are only committed to superior quality: we have original equipment (OE) as the standard," says CEO Gwen Verfaillie, who highlights that SIDEM is a 'level 2' supplier in the assembly of new vehicles and is certified to the IATF 16949 standard.

"But that's not all: superior quality is also synonymous with reliability for our customers. SIDEM has an average service level of 98%, the highest score in the industry," says Gwen Verfaillie.

A promising future

"We are looking forward to the future and the electrification of vehicles," says Iwan Loewen. As battery electric vehicles still need steering and suspension components, SIDEM is ready for the future!

Because electric vehicles are heavier and develop more initial torque during acceleration, there is a higher demand for their products in the aftermarket, for which SIDEM has an extensive portfolio (see box).

"It is very clear: SIDEM will continue to focus on customer satisfaction through superior quality products in the steering and suspension parts segment, while maintaining the maximum coverage and level of service. Even in 'new' segments such as battery electric vehicles, SIDEM already has the largest product offering in the aftermarket," says Gwen Verfaillie.

Specialized Parts for Electrical Transition

As more cities adopt low-emission zones and the European Union requires all new cars to be CO2-neutral by 2035, the shift to electrification in the automotive sector is inevitable.

The number of electric vehicles in Europe has increased from 1% in 2017 to 9% in 2021, according to the European Association of Automotive Suppliers (Clepa). In addition, the World Economic Forum predicts that 300 million electric vehicles will be in use in the U.S. by 2030.

SIDEM's range of BEV steering and suspension parts includes 960 unique references for 32 European and Asian brands, covering 84% of the aftermarket. No other company offers such quantity and quality coverage for BEV-matched steering and suspension parts.

Despite the shift to electric vehicles, the impact on the aftermarket for steering and suspension parts is relatively limited. However, BEVs are heavier than gas-powered cars because of their battery pack, which puts extra strain on the steering and suspension parts. According to the company, SIDEM's range of BEV parts has been designed to withstand the extra weight and torque, ensuring maximum strength and safety.

Some examples of SIDEM designs in its BEV components: larger diameter ball bolts embedded in ball joints, axial joints and stabilizers, suspension arms with ball joint incorporated into the aluminum housing, Silentblocks with extra metal ring or hydraulic spaces for greater driving comfort.

To find out more about Sidem's range of steering and suspension parts for BEVs and other vehicles, you can visit www.sidem.eu.