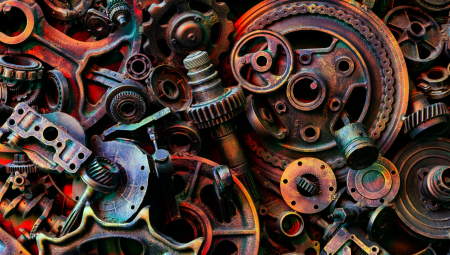

RC Fuel Injection

Direct injection has become increasingly popular with vehicle manufacturers because it can precisely deliver a specific amount of fuel into the combustion chamber. But, like port injectors, they can and do clog. In addition to fuel related clogging, direct injector tips can become contaminated with carbon from combustion events.

RC explains that it starts by flowing the injectors at up to 300 bar fuel pressure (depending on system requirements) and documenting the results.

In the process, all components subject to wear (O-rings, seals, filters, etc.) are replaced. The reconditioned injector is then flowed again to determine the volume and evaluate the spray pattern.