International. The BMW Group reported that it will significantly reduce its carbon footprint by 2030 through the research and development of innovative materials. This will focus on renewable raw materials and recycled materials.

According to the group, "it relies more on new, forward-thinking materials that save resources in the fight against climate change. This represents an important element of the sustainability strategy." "The BMW Group aims to meet its own climate targets extremely by drastically reducing its carbon footprint per vehicle by 2030. This is boosting the use of secondary materials with the introduction of the 'Neue Klasse' and intensifying research and development of sustainable materials and substances used in vehicles."

In addition to the work of research and development of resource-saving materials, the main priority will be to combine sustainability and premium quality, as Uwe Köhler, Head of Body, Exterior and Interior Development emphasizes: "We are setting new standards for sustainable superior quality. Quality. This path forces us to rethink materials, focusing even more specifically on resource-saving material alternatives and renewable materials that have an outstanding capacity to be dismantled. This represents a firm path: a path towards the integral development of sustainable products, the responsible use of resources and the transformation towards a circular economy."

Natural raw materials

The use of renewable raw materials and natural fibers such as hemp, kenaf and flax not only minimizes the use of materials, but also reduces the weight of the vehicle. For the group "this has a positive effect on the CO2 footprint, since natural fibers absorb CO2 while emitting oxygen during their growth phase."

They are also researching new types of wood foams. Wood foam is made up of 100% renewable raw materials and is so strong that it completely eliminates the need for synthetic adhesives.

Sustainable materials are the basis for resource-saving car construction. The BMW Group has defined several material groups, all of which cover the four areas of the circular economy: RE:THINK, RE:DUCE, RE:CYCLE and RE:USE.

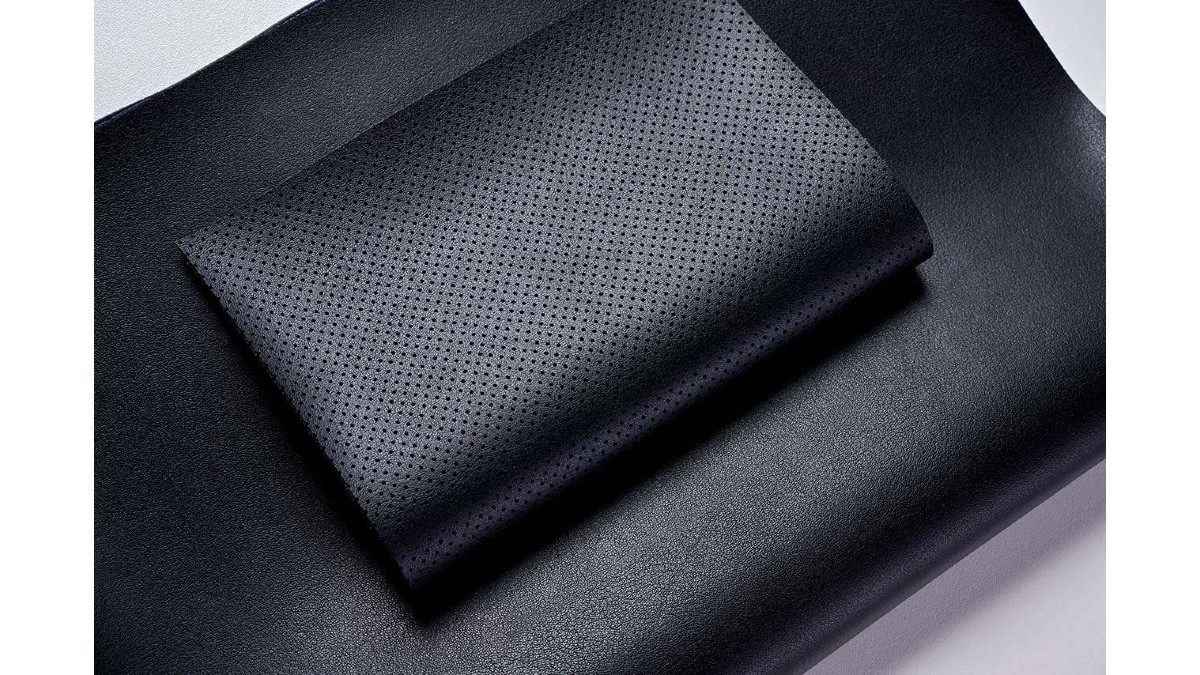

Recycled plastic and alternative to leather

"The BMW Group already relies on 100% recycled plastic, i.e. recycled materials, for thermoplastic components. Together with innovative plastics manufacturers, it is constantly working on the development of new recycled plastics and bioplastics with particularly low carbon footprints," the manufacturer said.

It is also working with innovative start-ups to explore new possibilities in vegan leather alternatives: artificial leather with bio-based raw materials, 100% recycled polyester fabric and cork particles that reduce CO2 emissions by up to 45% compared to today's PVC artificial leather.

On the other hand, they are articulated with the start-up Adriano di Marti SA de CV to investigate a sustainable material called Deserttex TM, which consists of powdered cactus fibers and a bio-based polyurethane matrix. The fully recyclable Mirum TM also offers a conscious alternative to traditional leather. The BMW Group's involvement with the start-up Natural Fiber Welding opens up new opportunities in the development and implementation of plant-based material options.

Leave your comment