Latin America. Along with the move to electromobility, refrigerants for air conditioning systems are driving a change in the automotive industry.

By Aftermarket International

Standards set by regulations from international environmental agencies have led manufacturers in the automotive industry to adopt low-emission refrigerants.

The European regulation F-GAS, for example, which came into force on January 1, 2015, proposes the progressive reduction of emissions by controlling the use of fluorinated greenhouse gases in that region, replacing them with other types of gases with a lower Global Warming Potential (GWP) before 2030.

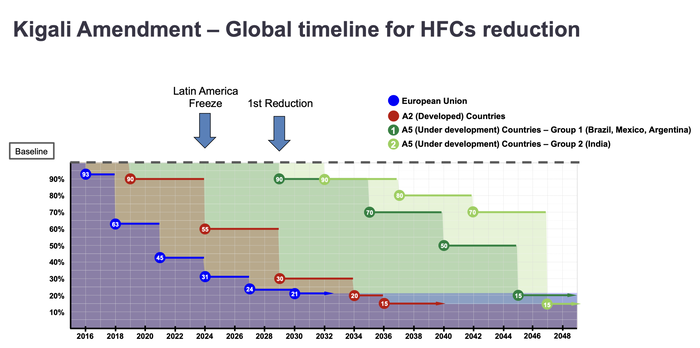

Already in 2016, 197 countries signed the Kigali Amendment to the Montreal Protocol, which provides that over the next 30 years the production and consumption of hydrofluorocarbons (HFCs), organic compounds used as alternative refrigerants to ozone-depleting substances, regulated by this protocol, will be reduced by more than 80%.

One such greenhouse gas is HFC-134a, a standard refrigerant in vehicle air conditioning units that permeates nearly 100% of Latin American industry. That's according to Inaise Balestero, Chemours' regional account manager for the automotive sector in Latin America.

According to Balestero, this chemical compound has a global warming potential 1300 times greater than CO2, which is the substance used as a measurement parameter.

Thus, based on the international schedule established to reduce the use of greenhouse gases, the chemical industry began to work on a molecule with lower global warming potential with optimal thermodynamic properties and similar energy efficiency.

"The idea was that you could develop a molecule that was virtually identical in terms of property so that you could make a conversion easier in industry," he says.

"The idea was that you could develop a molecule that was virtually identical in terms of property so that you could make a conversion easier in industry," he says.

In this way, after years of development, companies such as Chemours produced the refrigerant R-1234yf. It has a global warming potential 99.9% lower than its predecessor, R-134a. The significant difference is due to R-1234yf being a hydrofluorolefin (HFO), a molecule with a short lifetime in the atmosphere. While R-134a remains in the atmosphere for 12 years, the lifetime of R-1234yf is only 11 days.

Such refrigerant is mildly flammable and requires the use of R-1234yf-specific automotive air conditioning tools. These include compressor oil, injection adapters for leak detection, and air conditioning recovery machines.

"The industry looked for a solution that could be long-term, easy to convert, and because of the schedule in the most developed countries, the change has already begun," he says. According to Balestero, nine out of ten cars in the United States already use R-1234yf, but in Latin America there is a longer timetable for its adoption.

With the demand for this product growing, the Chemours plant in the city of Corpus Christi, Texas, has been receiving investments to expand it and today has the largest production capacity in the world.

With the demand for this product growing, the Chemours plant in the city of Corpus Christi, Texas, has been receiving investments to expand it and today has the largest production capacity in the world.

Preparation in Latin America

The international timetable of the Kigali Amendment has set a freeze on greenhouse gas imports from 1 January 2024, with the first reduction planned for 2029.

However, countries such as Mexico, Brazil and Argentina also import cars from the U.S. and Europe that have already adopted this technology, so the refrigerant is already circulating in the region. "That's why it's important for the service sector to be prepared, because there are already cars circulating with this product around here," says Inaise.

Technical Specifications

"Refrigerant gases are like the blood of refrigeration equipment that circulates throughout the system, and there is an international standard that standardizes the composition standards of a refrigerant," says Inaise, referring to the AHRI 700-2012 standard, which meets the specifications that Fluorocarbon Refrigerants must meet.

Inaise stresses the importance of considering these specifications, as there are many imported refrigerants that are not from safe suppliers. This can not only compromise the energy efficiency of a piece of equipment, but also cause very serious damage to the system such as the burning of compressors.

Among the characteristics verified in the standard are moisture (ppm by weight), acidity (ppm by weight), non-condensable gases and volatile impurities (percentage by volume).

"That gas has to have a maximum of 10ppm of humidity because H2O can generate acid in the system, which can lead to oxidation of the pipes, and ultimately all that contaminated fluid can reach the compressor and generate a flare," warns the Chemours professional.

These were precisely some of the most common concerns received during a recent fair in Brazil, FEBRAVA as well as AAPEX, where the company was present and recalled the value of a good quality and certified refrigerant that results in a friendly contribution to the environment.

Leave your comment